Center of sheet metal, plastics and composite panel processing

Firm Heikkinen was established in 2011 year.

Our goals at that moment were: to secure a foothold in the market as a producer of light constructions made of metal profiles and create a competitive machine park, which would permit in the future to reach a new level of quality and enter such a market segment as processing of sheet metal and plastic.

During the first and following years of work our company acquired a good position in the market and earned a reputation of the reliable partner.

Now we work two or three shifts per day and develop constantly.

Our assortment of services and possibilities is growing as does the experience.

We are prepared for new challenges! We are prepared to become your partner!

Inquiry

Equipment

Automatic system of loading and unloading material.

High speed, high quality

Finn Power A5 expressModern machine with wide array of options, such as index instruments, hatch for small details, possibility of marking, automatic loading of sheet metal, automatic unloading of material, conveyer of wastes etc.Parameters of processed sheets: 1250x2500Maximal sheet thickness: 3mm

Technical specifications:

- Automatic loading of sheet metal

- Automatic unloading of sheet metal

- 46 instruments in the drum

- 7 index stations

- Load – 20 tons

- Maximal thickness of sheet metal: 3mm

- Maximal parameters of sheet without reposition: 1250x2500

- Forming to one side is possible

Modern system of control, 6 spindles, high precision.

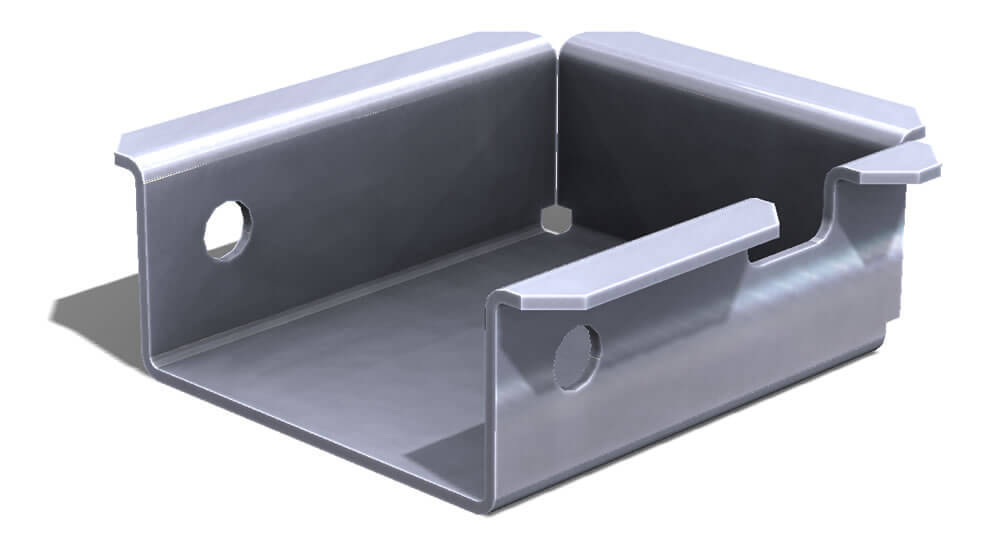

High speed, high quality

Amada HPF 80-25Modern bending machine with length of the table up to 2500 mm, maximal load 80 tons, wide variety of tools for metal bending (including for stainless steel)Amada – is the acknowledged leader in the field of metal bending.

Technical specifications:

- Maximal load: 80 tons

- Table length: 2500 mm

- Wide variety of tools

- High precision and speed of the machine

- 6 spindles

- Special instruments for work with stainless steel

The most modern vertical saw in Estonia designed for cutting plastic panels.

Large saw with multitude of possibilities

Putsch Meniconi 6000*2100Vertical formatting saw with working area of 6*2,1 m and multitude of additional functions. It allows carrying out high quality and fast cutting operations with plastic, aluminum and composite panels as per client’s specification.

Technical specifications:

- Working area: 6000*2100 mm

- Depth of cutting: up to 80 mm

- Possibility of cutting patches of material

- Double system of dust absorption

- Digital positioning of plates

- Wide array of additional equipment

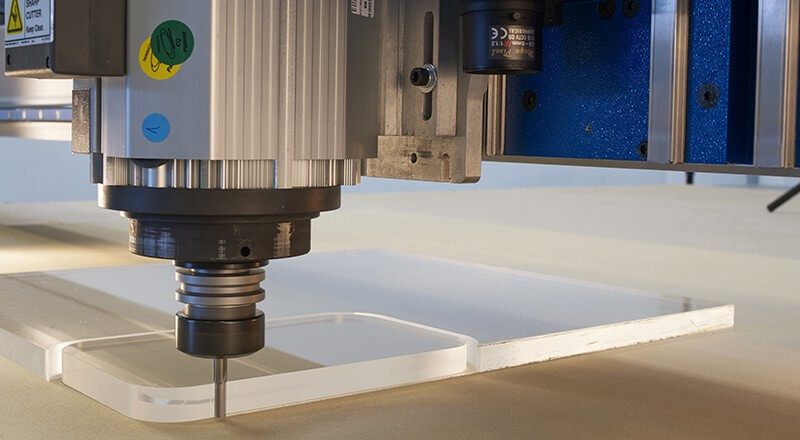

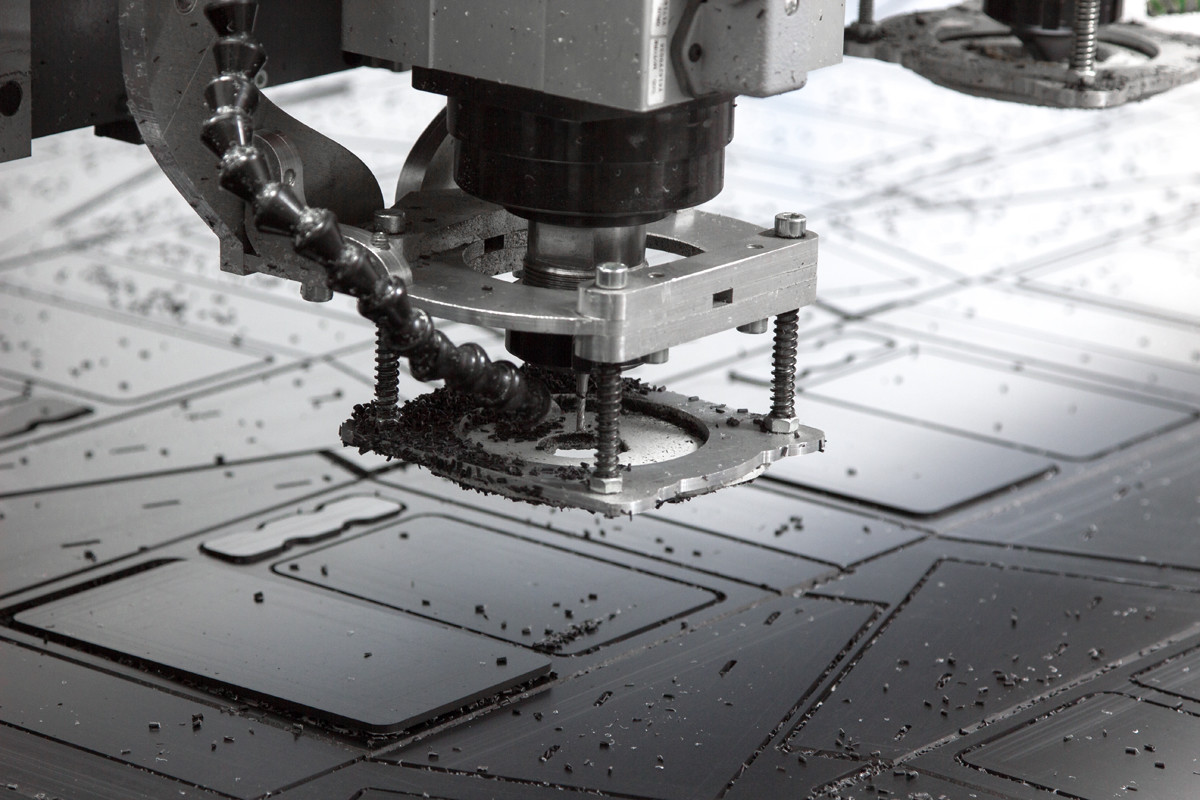

CNC milling machine for cutting plastic.

Milling machine with multitude of possibilities

AXYZ 4016CNC milling machine with a working area - 2050х3050mm and many additional functions allows qualitatively and quickly to milled plastic, aluminum or composite panels.

Technical specifications:

- Working area - 2050mm X 3050mm

- Spindle - 10 hp

- Height - 150mm

- Automatic tool change (8 cutters)

- Cooling system for milling metals

- Vacuum clamp (7.5 kW pump) with zone adjustment

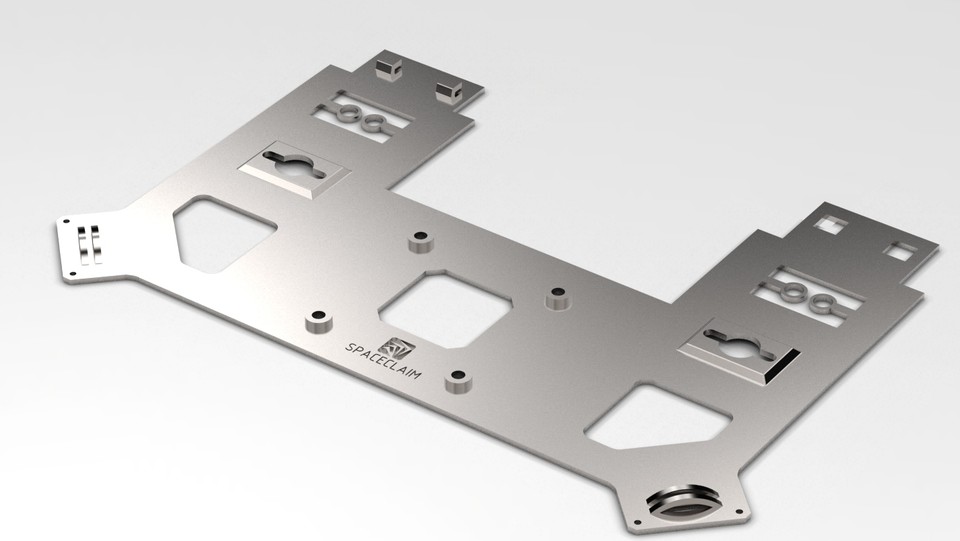

CNC milling machine for cutting composite panels.

Milling machine with multitude of possibilities

AXYZ 6010CNC milling machine for composite panels. Working area - 2120x4870mm, a lot of additional functions make it possible to quickly milled large-sized composite panels.

Technical specifications:

- Working area - 2120х4870mm

- 2 independent 5-hp spindles.

- Special equipment for milling composite panels

- Vacuum clamp (7.5 kW pump) with zone adjustment

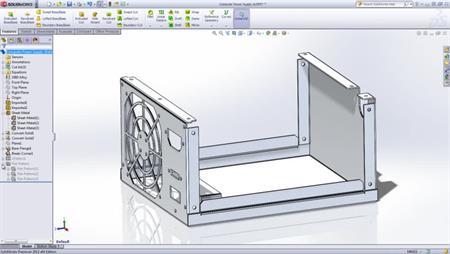

Services:

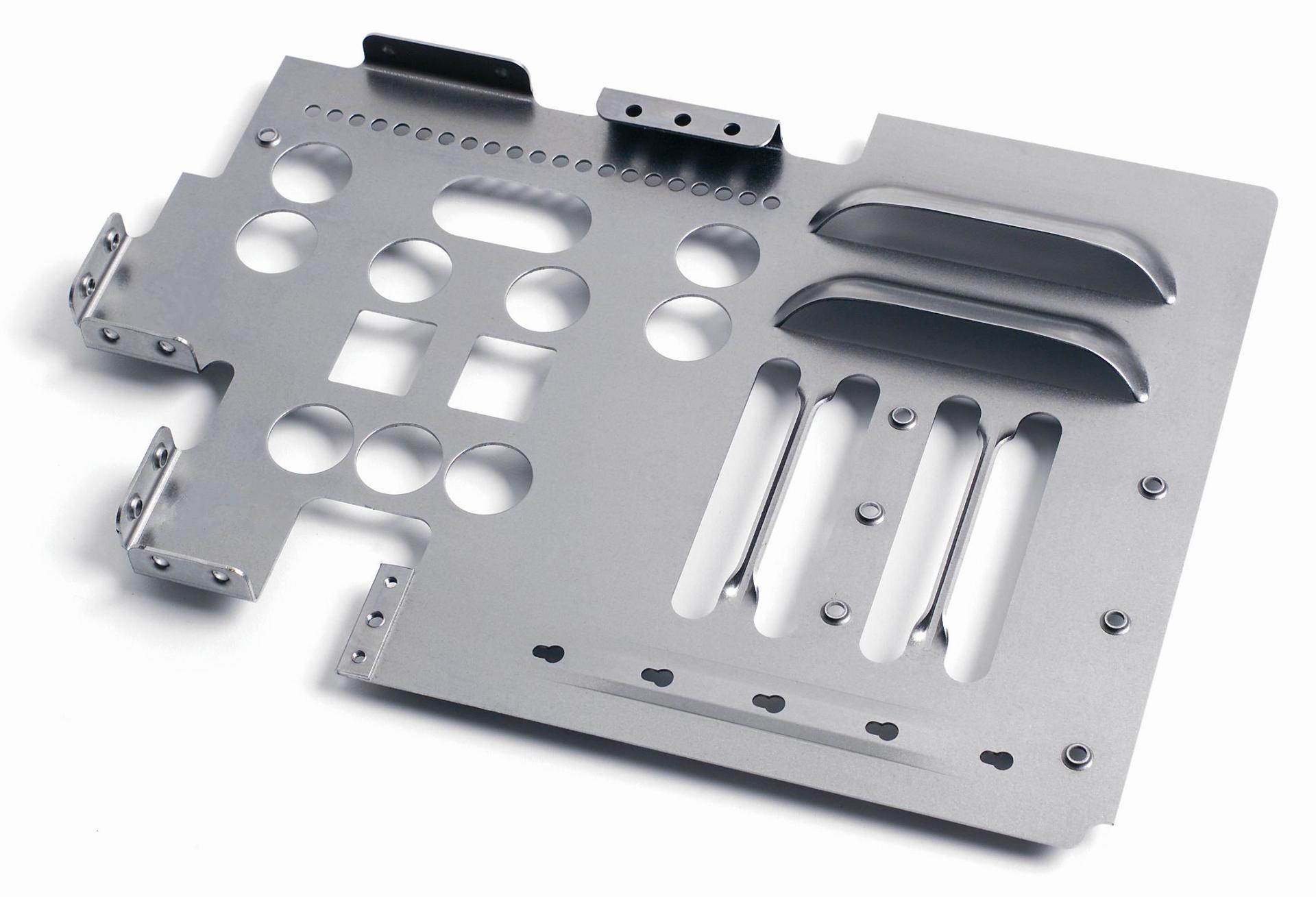

Punching / forming / perforation

The equipment can punch sheet metal (of different grades), plastic as well as composite panels.

Bending of metal and plastic

Wide assortment of instruments for bending machine allows making high-quality precise bends for production of complicated parts.

Cutting plastic and composite panels

The most up-to date vertical saw in Estonia allows cutting materials in thick packs (up to 80 mm) that significantly speeds up the process of cutting.

Installation PEM-components

REM-components are an indispensable part of modern enterprise, processing sheet metal.

Assembly and packing workshop

Specialists of assembly and packing line are well-trained and learnt new methods and processes of assembly, where modern equipment is used.

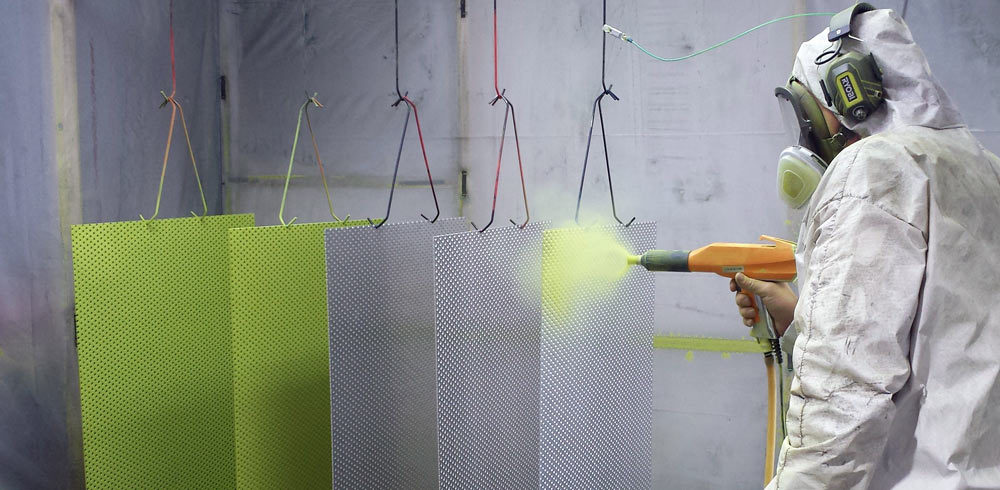

Powder coating

Painting is carried out on the territory of partners, using equipment, conforming modern norms.

Milling of plastic and composite panels

Milling is performed on CNC machines. Modern equipment and technologies are used, which increase the speed of production and have a positive effect on the quality of the finished product.

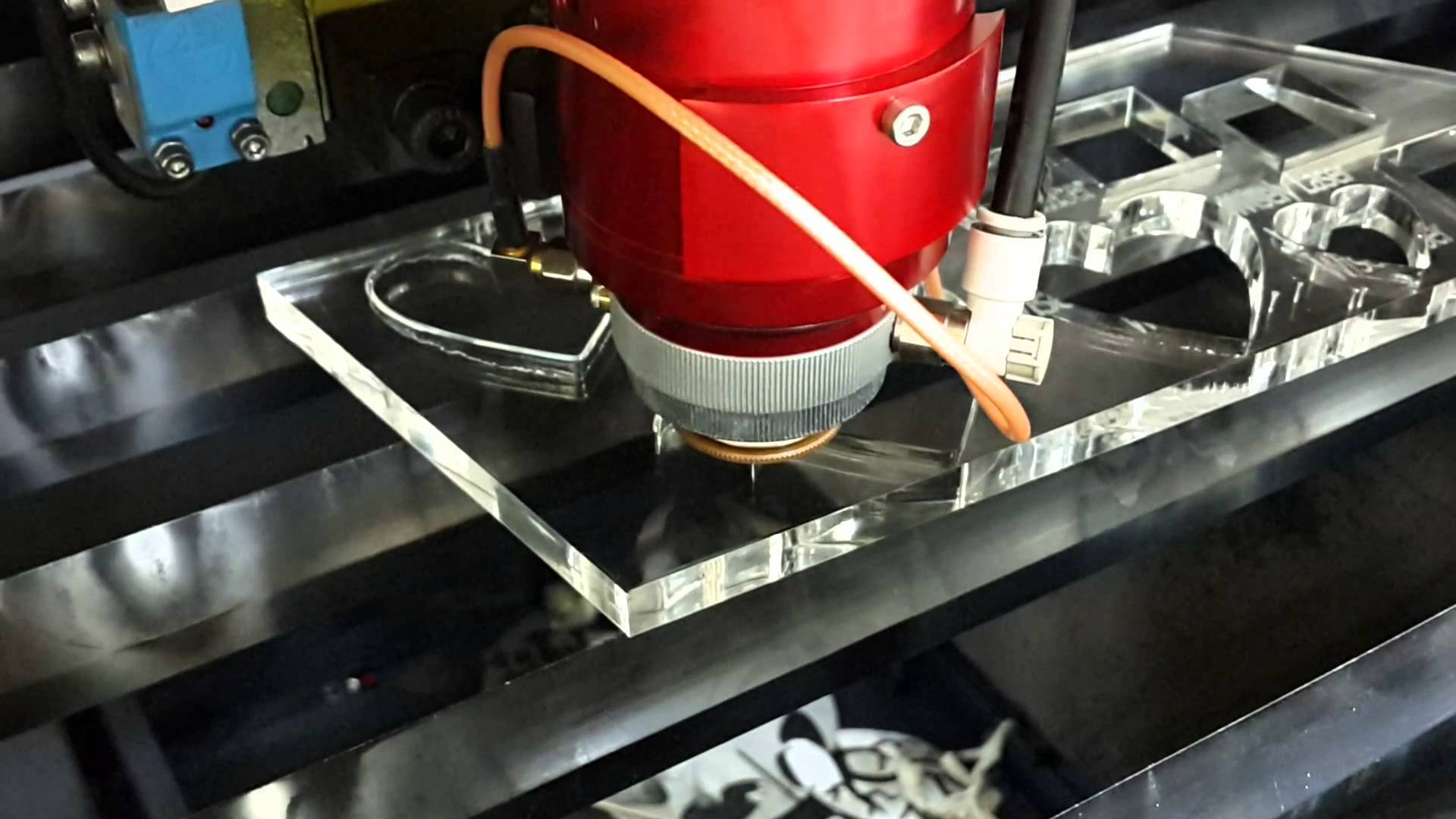

Laser cutting

The laser cutting machine allows precise cutting and engraving of different types of plastic up to 10mm thick.

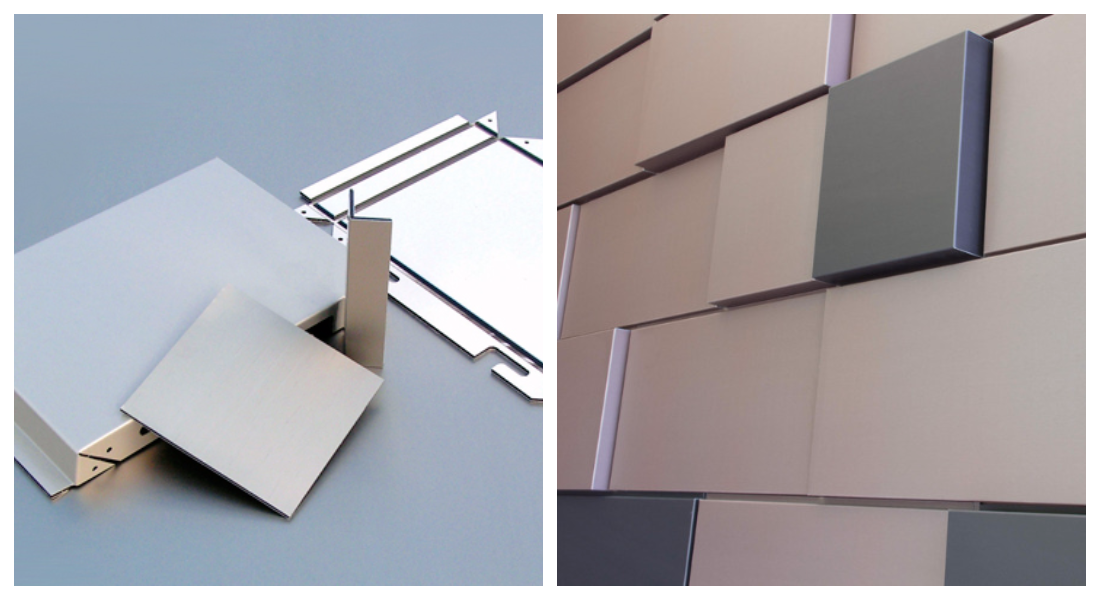

Facade cassettes

The milled composite panels are assembled in our factory, further cassettes can be delivered to the partner's construction site in assembled form for quick installation to the facade.

Engineering

Technical services related to the development and preparation of the production process and ensuring the normal course of production..

Inquiry

Heikkinen – your reliable partner

Priorities of our work with clients are in the following:

The Manager of the project negotiates with the partner, makes calculation of the project, consulting with the Technical Engineer. The project from the very start is led by the manager, who controls all the stages of production, from time and quality of implementing the order, to packing and delivery of the product to the client.

Such a method allows the manager of the project to pay a special attention to requirements of the client , to delve into details of the order, to make clear all the peculiarities of its production, that will allow to take more competent and fast decisions and offer solutions to parallel questions.

7 years in business

Modern equipment

AAA credit rating

High level of automation

ADVANTAGES

Punching, cutting, stamping, perforating etc. with automatic sheet metal uploading and unloading system.

This function allows our company to perform fast high-quality work, leading to minimum at the same time influence of personal factors due to the automatization. Taking the above into an account we can guarantee competitive price and fast completion of orders. Completely automatized production line ensures three-shift non-stop work without participation of an operator.

Modern machines of acknowledged producers of equipment.

Our company owns exceptionally safe machines of European produce, which are maintained and supported by a service center in Estonia. It allows to guarantee our partners high quality of production performance and fast repair of any malfunctions, that will not influence on time of finishing the order.

Highly-skilled personnel.

The commercial director has many-years’ experience of partnership with large scale companies: supply companies and clients of fabricated sheet metal.

The technologist and the technical engineer have acquired high skills during the 9 years’ experience of work with leading in the industry enterprises

The operator of-punching press has worked for 9 years with equipment of such leading producers as Amada, Prima Power, Trumpf and is a real professional in the field.

The senior operator of bending machine has an experience of more than 12 years of work with bending machines Amada and is a professional of high level.

Warehouse

For the operative work with partners at our warehouse we always have at stock galvanized steel (Dx51/Z275) in plates with dimensions 1250x2500 and thickness 0,5мм-3мм

Dates of delivery of different types of steel, aluminum, plastic and composite material to our workshop are within 3 working days.

For some partners we produce goods, which can be stored at our warehouse. It allows reacting fast making immediate shipments of finished products to our partners.

Inquiry

Partners

HYRLES OÜ

Kalmari tee 12, Karla küla, Rae vald, Harjumaa 75327

Favor AS

Loovälja tee 11

Liivamäe küla, 74207 Jõelähtme vald

Harju maakond

Valdek AS

Piiri 12A, Keila linn, Harjumaa 76610

Saku Metall AS

Põrguvälja tee 25, 75306 Rae vald,

Harjumaa, Eesti

HEIKKINEN OÜ

+ 372 5284100

info@heikkinen.ee

Piloodi tee 4, Soodevahe küla, Rae vald, Harjumaa, Eesti

Swedbank a/a: EE822200221051708596

SWIFT HABAEE2X

IBAN EE822200221051708596

VAT: EE101517201

Reg № 12054291

E-R 8:30-17:00

Политика конфиденциальности

Редактируемый текст

Данный сайт использует Cookie

Редактируемый текст